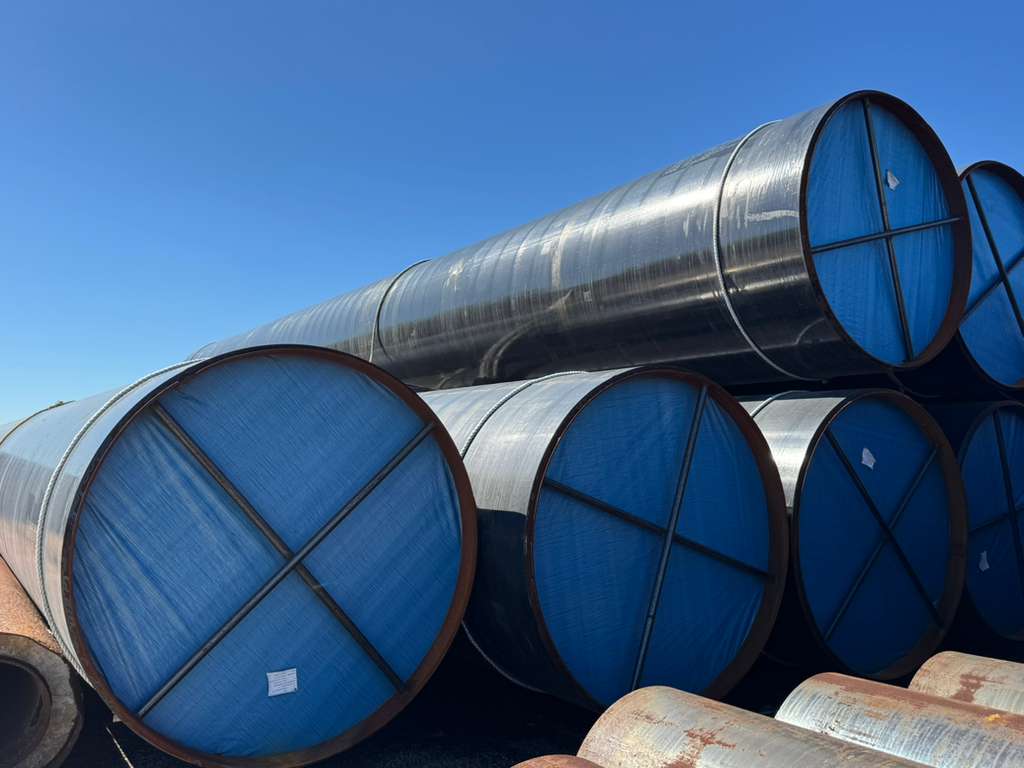

DSAW Pipe: Double Submerged Arc Welded Steel Pipe

Double Submerged Arc Welded (DSAW) pipe is a high-strength steel pipe manufactured using a specialized welding process that ensures superior durability and reliability for demanding applications. It is produced by forming a single piece of steel plate into a cylindrical shape through rolling or pressing, followed by welding the longitudinal seam on both the inside and outside surfaces using submerged arc welding. This “double” welding technique—where the arc is protected by a layer of flux—creates a robust, fully penetrated weld that minimizes impurities and enhances structural integrity. DSAW pipes are available in straight-seam or spiral-seam configurations, with spiral variants (also known as HSAW) featuring a helical weld for longer lengths up to 155 feet.

Key Features and Benefits

- High Weld Quality and Strength: The double-sided welding process penetrates 100% of the pipe wall, providing exceptional resistance to pressure, tension, and corrosion—ideal for high-stress environments.

- Dimensional Precision: Pipes can be specified to exact inside or outside diameters, with sizes ranging from 16 inches to over 72 inches in diameter and wall thicknesses from 0.375 inches to over 1.5 inches.

- Versatile Manufacturing: Produced via methods like pyramid rolling or U-O-E pressing, and often cold-expanded for tight tolerances. Surface treatments such as sandblasting further extend service life by preventing rust.

- Compliance and Customization: Meets standards like ASTM A252, API 5L, and ASME SA333, with options for custom lengths and grades suitable for various industries.

Common Applications

DSAW pipes excel in large-diameter, heavy-duty uses, including:

- Oil and gas transmission lines and offshore pipelines.

- Structural piling and foundation work in construction

- Infrastructure projects like bridges, tunnels, and load-bearing supports.